5 Practical Tips for Effective Supply Chain Optimisation

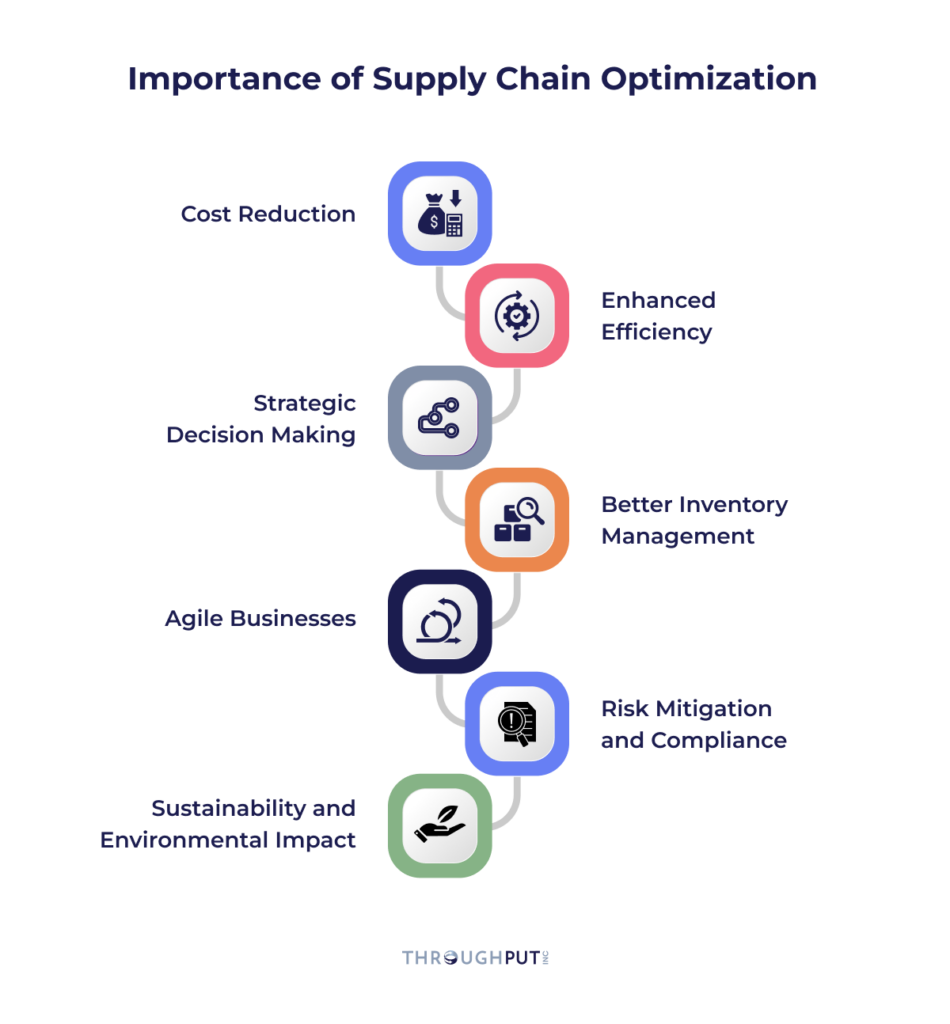

Supply chain optimisation is crucial for efficient operations, reducing costs, and increasing competitiveness. As supply chains become more intricate, with changing consumer demands and unexpected disruptions, streamlining these processes is essential. With effective strategies and technology, businesses can turn supply chains into valuable assets.

Our guide, “5 Practical Tips for Effective Supply Chain Optimisation,” covers key strategies for resilient, agile supply chains. Implement advanced forecasting, use technology and automation, strengthen supplier relationships, and improve inventory management. Continuous process analysis is vital for both immediate improvements and long-term benefits. Whether addressing inefficiencies or aiming for excellence, these strategies can transform your supply chain and support sustainable growth.

Advanced Forecasting Methods in Supply Chain

Accurate demand prediction is key to optimising supply chains. Transitioning from traditional forecasting to advanced machine learning models enhances this ability. These technologies provide a more precise prediction of demand, crucial for effective supply chain management.

Advanced forecasting boosts prediction accuracy and aligns stakeholders. This alignment improves market understanding and avoids inefficiencies. Industry data shows companies using machine learning can reduce forecasting errors by up to 45%, strengthening supply chain resilience.

These techniques minimise overstock and stockouts, common issues that disrupt supply chains. A case study involves a consumer electronics company that improved inventory management by 25% using predictive analytics. This efficiency cut storage costs and ensured timely product availability, enhancing consumer trust.

As supply chains grow global and dynamic, data-driven forecasting becomes vital. Adopting these technologies sets organisations up to leverage technology and automation, crucial for streamlining operations and optimising supply chains further.

Leverage Technology and Automation

Optimising supply chains is crucial for success. Utilising technology and automation can greatly improve a supply chain’s efficiency. AI, IoT, and analytical platforms help companies excel. Here are strategies to transform your operations.

The Internet of Things (IoT) has revolutionised supply management, enabling real-time tracking and predictive analytics. An interconnected device network offers real-time updates on goods, reducing risks, delays, and ensuring timely delivery. Companies using IoT see significant gains.

Artificial Intelligence (AI) predicts patterns and refines processes, aiding in forecasting, route optimisation, and inventory management. This leads to cost savings and efficiency.

Data analysis platforms like Microsoft Power BI enable quick data visualisation and insights, enhancing decision-making and process efficiency.

Blockchain brings transparency with a secure ledger system, ensuring data security and visibility, reducing errors, and fostering consumer trust in products.

Technology aids critical supply chain components like inventory management. Discover more in our next section: Optimise Inventory Management.

Optimise Inventory Management

Effective inventory management is key to optimising your supply chain. By implementing Just-In-Time (JIT) systems, you maintain ideal inventory levels to meet orders precisely, reducing waste and overproduction. JIT fosters a smoother product movement, enhancing efficiency.

Advanced inventory software provides real-time stock visibility, automating orders to keep inventory at optimal levels, and cutting storage costs. It allows quick responses to market changes, preventing stockouts and overstock.

Partnering with dependable suppliers is crucial for minimising inventory costs through coordinated deliveries. Strong supplier relationships synchronise with business goals, offering flexibility and reliability. Adapting to market trends is necessary, and solid supplier alliances ensure strong and responsive supply chains.

Strengthen Supplier Relationships

Building strong supplier partnerships is vital for supply chain success. Focus on these relationships after ensuring effective inventory management to enhance product quality, cut costs, and speed up market delivery—key factors for competitiveness today.

Regular supplier engagement is crucial for process optimisation. Joint planning sessions foster better understanding, leading to collaborative forecasting and realistic goal setting. Companies that hold frequent meetings with suppliers often experience greater efficiency and supply-demand alignment.

Supplier performance programs track efficiency via metrics and KPIs, promoting continuous improvement. It’s about discovering areas for enhancement and working together, fostering innovation for unique solutions.

Collaboration must rely on trust and long-term plans. Transparency ensures clear expectations and aligned objectives. A case study showed a firm cutting lead times by 20% through better collaboration, creating a more agile supply chain.

Ultimately, optimising supplier ties is beyond cost-saving; it’s about mastering collaboration to improve the supply chain processes fundamentally.

Optimise Supply Chain Processes

Optimising the supply chain starts with a precise analysis to find bottlenecks and inefficiencies. By evaluating each part, businesses can enhance operations to align with goals.

Analysing the process is crucial and helps companies improve delays, cooperation, and product flow. Use analytics for better setups that cut costs.

AI tools boost supply chain efficiency and reduce errors in demand forecasting and order processing, making processes agile. AI can lower forecast errors by 30%, improving inventory and resources.

To succeed, companies should train teams in AI and analytics. Onyx Data provides programs that fill skill gaps, improving process management by 21%.

Despite challenges, an optimised supply chain enhances accuracy, speeds delivery, and boosts customer satisfaction. Businesses adopting AI see significant improvements.

Improving supply chains requires commitment, but the benefits—lower costs, faster operations, better adaptability—are essential for achieving supply chain excellence.

Conclusion

Effective supply chain optimisation is crucial in today’s competitive business world. Advanced forecasting improves market demand predictions and boosts agility. By utilising modern technology and automation, businesses can increase efficiency and productivity, eliminating old inventory issues.

Building strong supplier relationships strengthens the supply chain, promoting success through cooperation. Ongoing analysis and refinements ensure businesses thrive in dynamic markets by highlighting inefficiencies and providing actionable insights.

Optimising your supply chain is a continuous journey requiring attention and foresight. Reflect on your strategies: Are you maximising your supply chain’s potential? Applying these strategies secures your present success and prepares you for the future. Ready to transform your supply chain? Start your optimisation journey today.

About Onyx Data

Onyx Data is a premier consulting firm specialising in advanced data analytics and AI integration with a core focus on Microsoft technologies such as Power BI and Microsoft Fabric. Our mission is to transform your data into powerful, actionable insights that drive business performance and informed decision-making.

In a rapidly evolving digital landscape, our expertise is crucial as businesses strive to harness the full potential of their data, bridging the AI skills gap while building scalable and efficient data systems. Trust Onyx Data to empower your enterprise to stay ahead in the competitive market with tailored solutions and training programs.

Transform your business with Onyx Data today! Visit our website for more information.